Food & Beverages - Mixing and diluting

In the food industry, many products are mixed to achieve the final product quality. In order to ensure this quality, constant monitoring is necessary.

Colour measurement

It’s sometimes said that people eat with their eyes. So the colour of the food product is very important. The correct colour and intensity can be determined by measuring the absorption of light.

Turbidity measurement

Do you want to control the clarity of the product or make sure it stays in suspension? A turbidity measurement is the right solution.

pH measurement

The degree of acidity or pH is a key parameter for many foods. It's important to make the right choice of pH electrode. Not only to obtain a correct measurement, but above all to minimise maintenance and calibration and to increase the service life. For years, the food industry has been asking for unbreakable electrodes. Several solutions are already available.

Refractometry

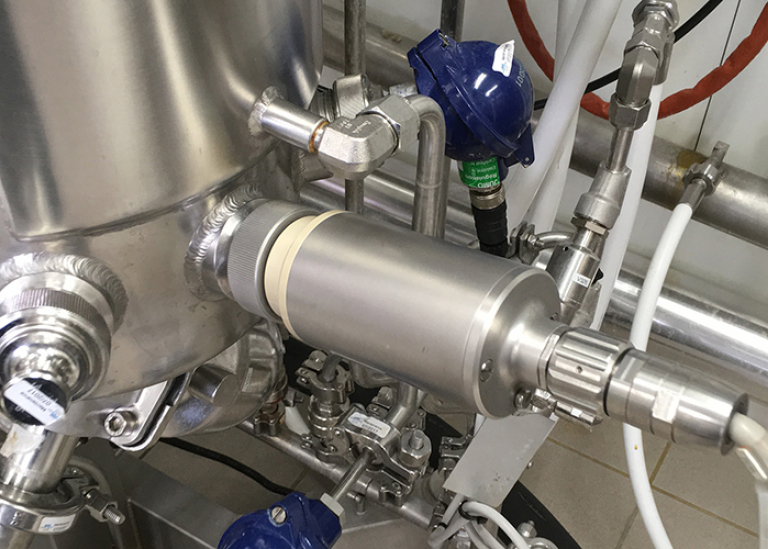

When you mix products with each other, add products or dilute them, the concentration of all components in the mixture changes. The measurement of the refractive index, refractometry, is the only direct measurement of the concentration of dissolved substances. By tracking the refractive index throughout the process, you get a fingerprint. This way, you know at any time whether your product meets the required quality or whether you need to make adjustments.

Conductivity measurement

For dosing salts and nutrients, a conductance or conductivity meter is a good choice. In most cases, we recommend an inductive sensor. They are very robust, resistant to corrosion and high temperatures and not sensitive to contamination, particles, fibres, etc.

More information?